Description

About Custom Slope Top Reverse Tuck End from Premium Product Boxes

What is Custom Slope Top Reverse Tuck End?

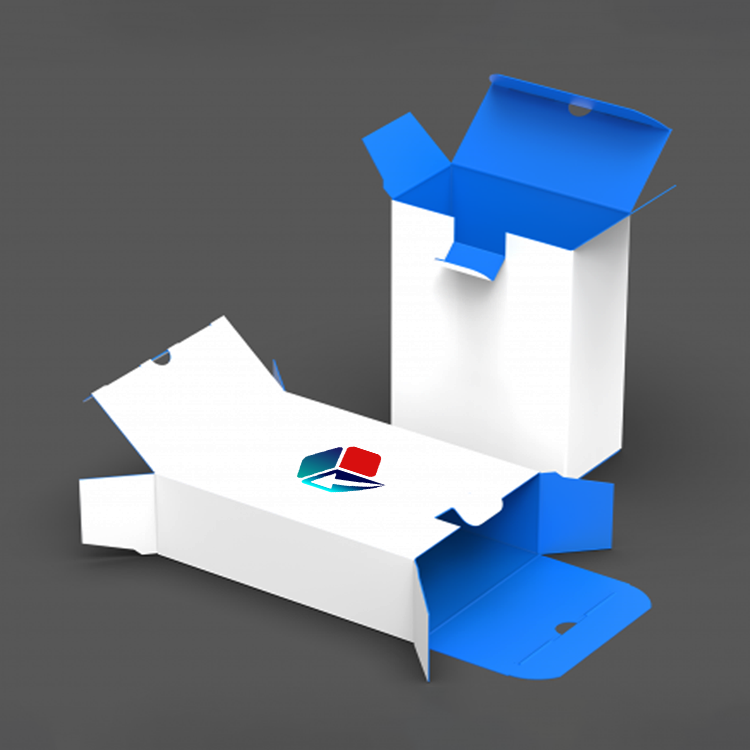

Custom Slope Top Reverse Tuck End is a unique packaging product designed specifically for businesses looking to create a standout presence on store shelves. Developed by Premium Product Boxes, this product combines style and functionality in a single package. A key feature of this design is its distinctive slope top which helps your product stand out from the crowd.

Benefits of Custom Slope Top Reverse Tuck End

Using Custom Slope Top Reverse Tuck End can greatly assist in increasing brand recognition. Its eyecatching design will immediately capture the attention of potential customers making it the perfect marketing tool for businesses. Moreover, the product’s durability allows for safe transportation of your items, further reducing the risk of damage.

Key Design Components of Custom Slope Top Reverse Tuck End

This unique design features a sloping top which not only adds a touch of elegance to your packaging but also protects your products from dust or moisture. With a custom design, you can imprint your company logo or branding elements on the packaging adding a touch of professionalism to your product.

Main Materials and Manufacturing Process of Custom Slope Top Reverse Tuck End

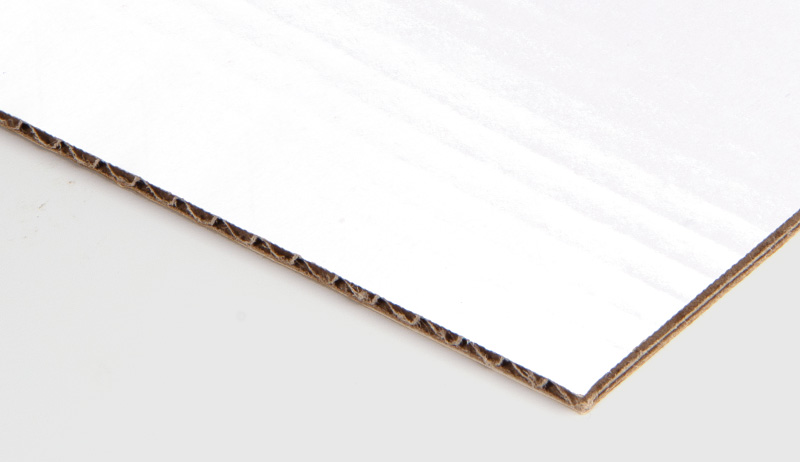

At Premium Product Boxes, we use premium quality materials for manufacturing Custom Slope Top Reverse Tuck End. Our products are constructed with sturdy cardboard providing a high level of resistance to wear and tear. With an advanced printing technology, we can print the custom design you desire directly onto the packaging ensuring precise color reproduction.

The manufacturing process of Custom Slope Top Reverse Tuck End involves precise cutting, assembly, and printing to ensure each product meets our exceptionally high standard of quality. We also offer custom sizes for this packaging product to cater to unique product dimensions allowing businesses to make the most out of their product packaging.

Why Businesses Prefer Custom Slope Top Reverse Tuck End

Many businesses, particularly those dealing in consumer products, opt for Custom Slope Top Reverse Tuck End packaging due to its exceptional functionality, ease of use, and highquality finish. Our custom product provides businesses the flexibility to create a unique brand identity that reflects their company values.

The unique and stylish design of Custom Slope Top Reverse Tuck End will undoubtedly give your products the edge they need to stand out from the competition. By choosing Premium Product Boxes for this unique product, you can rest assured of delivering topquality products that meet all the packaging needs of your business.

Suitable Products for Custom Slope Top Reverse Tuck End Packaging

Types of Products Suitable for Custom Slope Top Reverse Tuck End Packaging

Custom Slope Top Reverse Tuck End packaging is suitable for a wide variety of products, mainly consumer goods and electronics, however it’s most suitable for products which are of medium to large size. Some examples include:

Beverage and drink packaging boxes:

Beer and wine gift boxes can benefit from Custom Slope Top Reverse Tuck End design as it can be designed with wine and beer bottle holders that perfectly fit the product.

Electronics packaging boxes:

Tablet and laptop packaging boxes are ideal for Custom Slope Top Reverse Tuck End boxes as these large products can be securely packaged in them and also can have custom molded inserts to prevent damage.

Food packaging boxes:

Pizza box, cake boxes, or cookie packaging boxes made of Custom Slope Top Reverse Tuck End can be designed with a window to show off the food product inside. This will not only add an aesthetic appeal but also will provide a clear view of the food quality.

Customizing the Design of Custom Slope Top Reverse Tuck End

Custom Slope Top Reverse Tuck End packaging is fully customizable which allows you to imprint your company logo, brand name, and even the product information directly onto the packaging. Our custom design options ensure that the packaging perfectly matches your brand image, making it a memorable representation of your products.

Types of Customization Options for Custom Slope Top Reverse Tuck End Packaging

Our packaging experts can customize Custom Slope Top Reverse Tuck End packaging in a range of ways including changing the:

Color scheme of the packaging to match your brand identity

Material type of the packaging to accommodate different product types

Size and shape of the packaging to fit specific products

Inserts can also be designed to fit inside the packaging for added protection of products such as molded packaging inserts or folded inserts

Pricing and Ordering of Custom Slope Top Reverse Tuck End Packaging

The pricing of Custom Slope Top Reverse Tuck End packaging is flexible, as it is dependent on factors such as product dimensions, material quality, and the scope of custom design. To find out more about our pricing options and to place an order for Custom Slope Top Reverse Tuck End packaging contact us and our customer support staff will assist you further.

Reviews

There are no reviews yet.