Description

Experience Customized Branding with Custom Reverse Tuck Boxes

At Premium Product Boxes, we know that first impressions matter, especially in the retail industry. Custom Reverse Tuck Boxes are an attractive solution for companies looking to create a professional image and differentiate their products from competitors.

What are Custom Reverse Tuck Boxes?

Custom Reverse Tuck Boxes are a unique type of packaging that uses a reverse tuck-end closure, providing a clean and sleek appearance. The design features a flat lid that folds inward toward the bottom of the box, creating a flush edge when closed. This style of packaging is both visually appealing and protective, making it ideal for products that are delicate or need extra care.

Key Features of Custom Reverse Tuck Boxes

– Customization Options: You can personalize your Custom Reverse Tuck Boxes with various design elements, including logos, colors, text, and shapes. Our team at Premium Product Boxes can help you choose the perfect design that reflects your brand’s identity and appeals to your target audience.

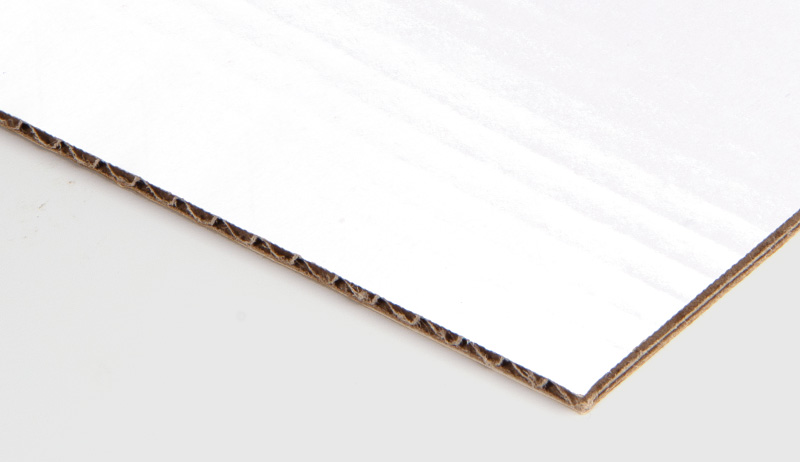

– Durable Construction: Our Custom Reverse Tuck Boxes are made from high-quality materials that ensure your products are protected from damage during shipping and storage. The sturdy design provides a secure fit for various product sizes and weights.

– Versatility: These boxes can be used for a wide range of products, including beauty and personal care items, pharmaceuticals, electronics, and more. Their customized design makes them suitable for various industries and businesses.

Benefits of Using Custom Reverse Tuck Boxes

Using Custom Reverse Tuck Boxes can bring numerous benefits to your business. Some of these advantages include:

– Enhanced Brand Recognition: Custom Reverse Tuck Boxes help create a consistent brand image, increasing brand recognition and recall among customers.

– Improved Product Protection: The sturdy design of these boxes ensures your products are well-protected, reducing the risk of damage during shipping and storage.

– Increased Customer Satisfaction: Custom Reverse Tuck Boxes add a professional touch to your products, showing customers that you care about the presentation and packaging of your items.

– Competitive Advantage: In a crowded market, Custom Reverse Tuck Boxes can help your products stand out, giving you a competitive edge over competitors who rely on standard packaging solutions.

How to Get the Most Out of Your Custom Reverse Tuck Boxes

To maximize the benefits of your Custom Reverse Tuck Boxes, consider the following strategies:

– Consistency: Use Custom Reverse Tuck Boxes consistently across all your products and marketing materials to create a strong brand identity.

– Branding Integration: Incorporate your logo and branding elements into the design of your Custom Reverse Tuck Boxes to reinforce your brand’s message and values.

– Product Placement: Use Custom Reverse Tuck Boxes to create eye-catching product displays that draw attention to your products on store shelves or in online product listings.

Order Custom Reverse Tuck Boxes Today from Premium Product Boxes

At Premium Product Boxes, our team is committed to helping you create high-quality Custom Reverse Tuck Boxes that reflect your brand’s unique identity. With our expertise and resources, you can choose from a wide range of design options, materials, and sizes to create a customized packaging solution that meets your specific needs.

Order Custom Reverse Tuck Boxes today and take the first step towards creating a strong and consistent brand image. Our team is here to guide you through the design and production process, ensuring that your custom packaging solution meets your expectations and exceeds your customers’ expectations.

Why Choose Premium Product Boxes for Your Custom Reverse Tuck Boxes?

At Premium Product Boxes, we pride ourselves on providing our clients with top-quality Custom Reverse Tuck Boxes that meet their unique needs and branding requirements. Some reasons why you should choose us include:

– Expert Design Assistance: Our team of experienced designers will work closely with you to create a custom design that meets your brand’s identity and appeals to your target audience.

– High-Quality Materials: We source our materials from trusted suppliers to ensure that your Custom Reverse Tuck Boxes are durable and long-lasting.

– Fast Production Times: Our state-of-the-art production facilities allow us to produce Custom Reverse Tuck Boxes quickly and efficiently, meeting your deadlines and reducing your production costs.

– Customer Support: Our dedicated customer support team is available to answer any questions and assist with any issues you may encounter during the design or production process.

By choosing Premium Product Boxes for your Custom Reverse Tuck Boxes, you can trust that you are working with a reputable and reliable partner who will help you create a customized packaging solution that exceeds your expectations.

Frequently Asked Questions about Custom Reverse Tuck Boxes

– What is the minimum order quantity for Custom Reverse Tuck Boxes?

Our minimum order quantity varies depending on the size and complexity of your design. Please contact us for more information.

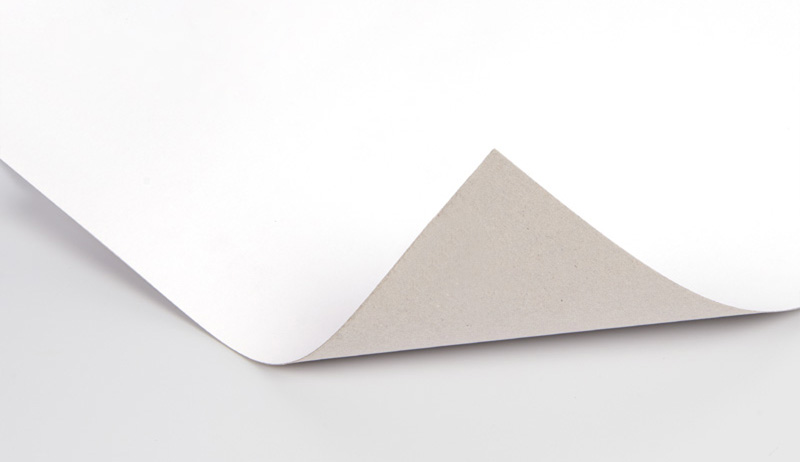

– What materials are used to make Custom Reverse Tuck Boxes?

We source our materials from trusted suppliers to ensure that our Custom Reverse Tuck Boxes are durable and long-lasting. Common materials include corrugated cardboard, Kraft paper, and recyclable paper.

– Can I customize the size of my Custom Reverse Tuck Boxes?

Yes, we can create Custom Reverse Tuck Boxes in a variety of sizes to accommodate different product shapes and weights.

Order your Custom Reverse Tuck Boxes today and start creating a strong and consistent brand image that resonates with your target audience!

Reviews

There are no reviews yet.