Description

About Custom Perforated Boxes

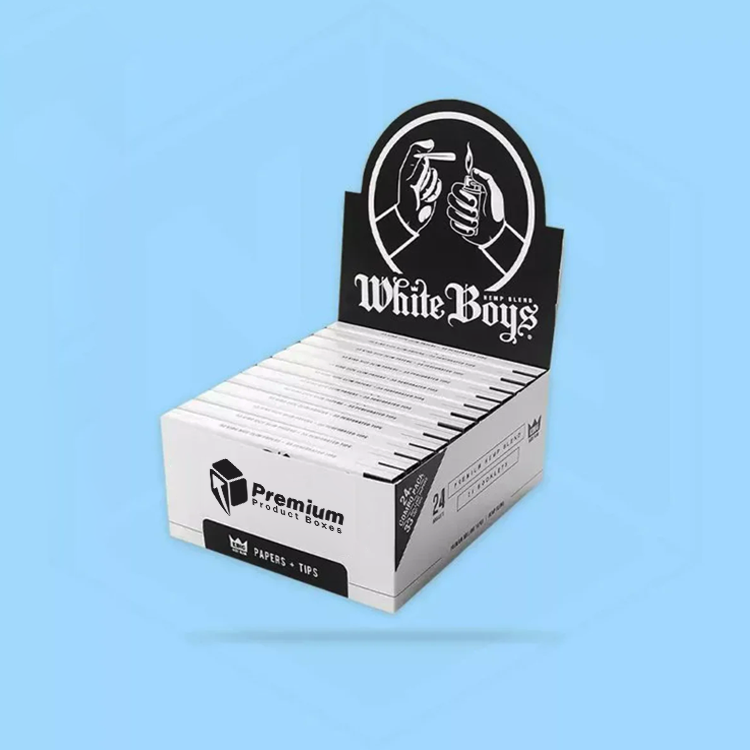

Custom Perforated Boxes are an essential packaging product used for various industries and applications. Premium Product Boxes is a renowned supplier of custom boxes that cater to diverse client needs. Our Custom Perforated Boxes serve as an effective packaging solution ensuring efficient storage, transportation, and handling of goods.

Features and Benefits of Custom Perforated Boxes

Custom Perforated Boxes offer distinct features that make them suitable for various industries. Some of the key features include:

Easy Opening and Closing: These custom boxes have prescored or perforated lines allowing users to easily open and close the boxes without any difficulty.

Enhanced Security and Protection: Custom Perforated Boxes are made from durable materials and designed to safeguard products from external damage, shock, and moisture exposure.

Efficient Space Management: These boxes have an adjustable divider that helps in organizing products, minimizing empty space, and maximizing storage capacity.

Customization: Custom Perforated Boxes are designed with the option to personalize box size, color, shape, and material to meet clients’ specific needs.

Types of Custom Perforated Boxes

Premium Product Boxes supplies a range of Custom Perforated Boxes tailored to various business requirements. Some of the primary types include:

General Purpose Boxes: These are simple and versatile boxes ideal for everyday use in packaging, storing, and shipping products.

Corrugated Boxes: Made from corrugated paper or cardboards, these boxes are lightweight and provide excellent protection to products from impacts.

Customized Boxes with Windows: These boxes allow users to inspect products inside without having to open the box which enhances the unboxing experience.

Custom Perforated Boxes for Various Industries

Premium Product Boxes caters to various industries that require custom packaging solutions. Custom Perforated Boxes are widely used in:

Ecommerce Companies: These boxes provide an excellent packaging solution to efficiently manage and protect goods, especially during shipping and storage.

Retail Businesses: Custom Perforated Boxes help retailers showcase their products and protect merchandise from damage while in transit.

Industrial Manufacturers: These boxes offer an efficient packaging solution for manufacturers to store, transport, and manage goods in a safe and organized manner.

Food and Beverage Companies: Custom Perforated Boxes are designed with foodgrade materials ensuring the safe and sanitary storage of products while also maintaining the quality of packaged goods.

Manufacturing and Production Process at Premium Product Boxes

At Premium Product Boxes, we employ a sophisticated manufacturing process to design, produce, and deliver custom boxes within short deadlines. Our manufacturing process includes:

Custom Designing: We work closely with clients to design custom boxes that meet their specific needs and requirements.

Material Selection: We source highquality materials and materials from trusted suppliers to fabricate the boxes.

Assembly and Production: We use stateoftheart machinery to efficiently assemble and produce the custom boxes.

Quality Control: Our quality control team ensures that all boxes meet industry standards, and every box meets client expectations.

Purchasing Custom Perforated Boxes at Premium Product Boxes

To purchase Custom Perforated Boxes at Premium Product Boxes, follow these easy steps:

Get in Touch: Reach out to our sales team or visit our official website to enquire about custom boxes.

Quote Request: Fill out a quote request form providing all requirements, specifications, and preferences.

Price Estimation: Our sales team provides a detailed price quote that includes custom box manufacturing costs.

Order Placement: Client confirms the order, and we start producing the custom boxes according to their specifications.

Packing and Shipping Information

Packing and Shipping Information

Once an order is placed for Custom Perforated Boxes at Premium Product Boxes, the production process begins. The following information outlines the packing and shipping procedures:

Packing Process

Packing Materials: We ensure that all boxes are packed with highquality packing materials to prevent damage during transit.

Labeling and Marking: We apply the client’s shipping labels and other necessary markings on the boxes.

Secure Packing: We pack the boxes in a way that prevents movement and impact during shipping and storage.

Shipping Methods

At Premium Product Boxes, we offer various shipping options to fit client requirements and deadlines. The following shipping methods are used to deliver custom boxes worldwide:

Ground Shipping: This method involves delivering the boxes via land transport which is suitable for shortdistance orders.

Air Shipping: We use air transportation for urgent orders or for clients that demand faster delivery.

Expedited Shipping: This method involves delivering the boxes within a specified timeframe, usually within 13 business days.

Free Freight: Some orders may be eligible for free freight, which is determined by the weight, size, and value of the products.

Timeline and Delivery Details

The delivery timeline for custom boxes at Premium Product Boxes varies based on several factors. The following information provides a general outline:

Production Time: Our average production time for custom boxes ranges from 24 hours to 10 business days, based on the complexity of the design and the order volume.

Shipping Time: Ground shipping typically takes 27 business days, while air shipping may take 13 business days.

Tracking Information: We provide tracking information for all shipments to ensure that clients can monitor their packages in realtime.

Delivery Timeframe: We strive to deliver all custom boxes within 714 business days from the date of receipt of the order.

Why Choose Custom Perforated Boxes at Premium Product Boxes?

Premium Product Boxes offers a wide range of benefits for clients who need custom packaging solutions. Here are some reasons to choose us:

Customization Options: At Premium Product Boxes, we offer a vast range of customization options for Custom Perforated Boxes, including size, color, material, and design.

Quality Materials: We source highquality materials and materials from trusted suppliers to ensure the durability and long lifespan of custom boxes.

Fast Production Time: Our efficient production process enables us to deliver custom boxes quickly, meeting tight deadlines and ensuring client satisfaction.

Cost Effective: Premium Product Boxes offers competitive pricing for custom boxes while maintaining the high quality of the products.

Reliability: We are committed to providing reliable packaging solutions to our clients, ensuring their satisfaction and loyalty.

Get in Touch with Premium Product Boxes

If you’re looking for a reliable partner to deliver highquality Custom Perforated Boxes, contact us today. Our team is ready to assist you in all your packaging needs.

With numerous years of expertise in packaging solutions, we provide our clients with innovative designs, timely deliveries, and excellent customer support. Whether you need custom boxes for a specific industry or just a generalpurpose box, Premium Product Boxes is your goto supplier.

To get in touch with us, simply visit our official website, fill out the contact form, or give us a call. We’ll be more than happy to help you find the perfect custom box solution for your requirements.

At Premium Product Boxes, we ensure timely deliveries and provide the highest quality Custom Perforated Boxes to meet your packaging needs.

Reviews

There are no reviews yet.